Sustainability Projects

Waste Managament 2021

EGCO Ecosystem – EGCO Group Waste Separation

EGCO Group believes that running the business and environmental concerns wherever it operates will contribute to overall sustainability. This project was initiated by “employees” through the “EGCO Ecosystem” project or internal waste separation project, which started in 2020 to raise awareness and encourage employees within the organization to separate waste correctly. This will lead to the formation of good behavior further.

4 types of waste are sorted out as follows:

In 2021, the EGCO Headquarters Building had a total recycled waste volume of 3,076.63 kilograms and an overall recycling rate of 60% (proportion in January - July 2021). This can reduce greenhouse gas emissions by 10.098 tons CO2 equivalent (data As of August 31, 2021). The EGCO Ecosystem project has received a certificate and certification from the Greenhouse Gas Management Organization (Public Organization) with satisfactory results.

To expand the results to the broader society, EGCO Group has also joined forces with the "Vibhavadi Zero Waste" project of the Securities and Exchange Commission. This is the beginning of building a circular economy.

Ash Management at Roi Et Green Power Plant

Roi Et Green Power Plant is a biomass power plant using rice husk as fuel. Rice husk ash from the combustion was tested by Department of Industrial Works and proved that it does not contain hazardous material.

Roi Et Green Power Plant therefore collects and transports the fly ash and bottom ash to ash storage room via a conveyor before loading to a modified truck provided with 4-side closed container for selling or giving the ashes to nearby farmers for making fertilizer or soil improvement. During transportation, the container is well covered and sprayed with water to reduce ash dispersion.

In 2021, the ash quantity of Roi Et Green Power Plant was 13,144.33 tons, of which, 45% was sold to be used for agricultural purpose, while the rest was distributed to government agencies and farmers.

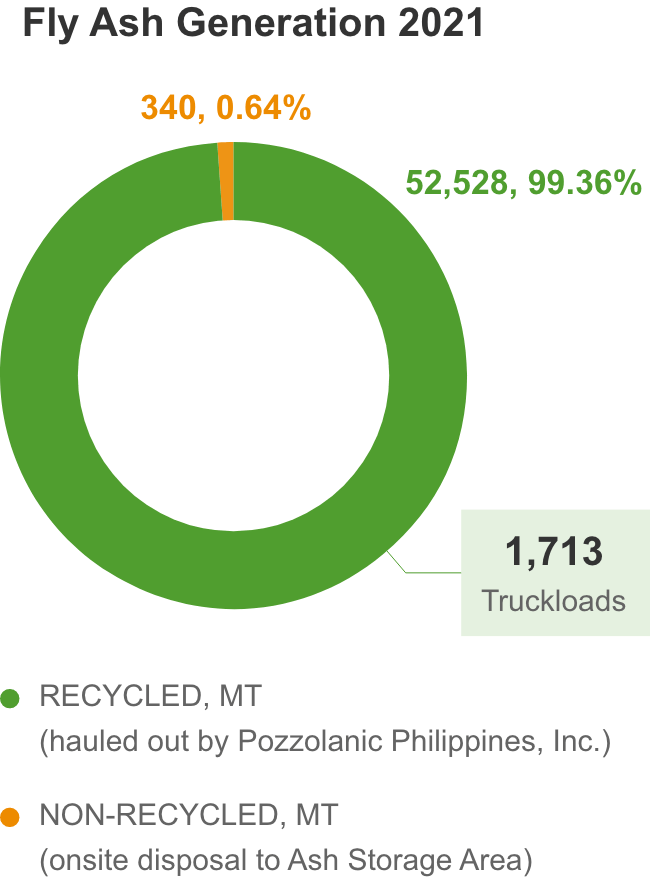

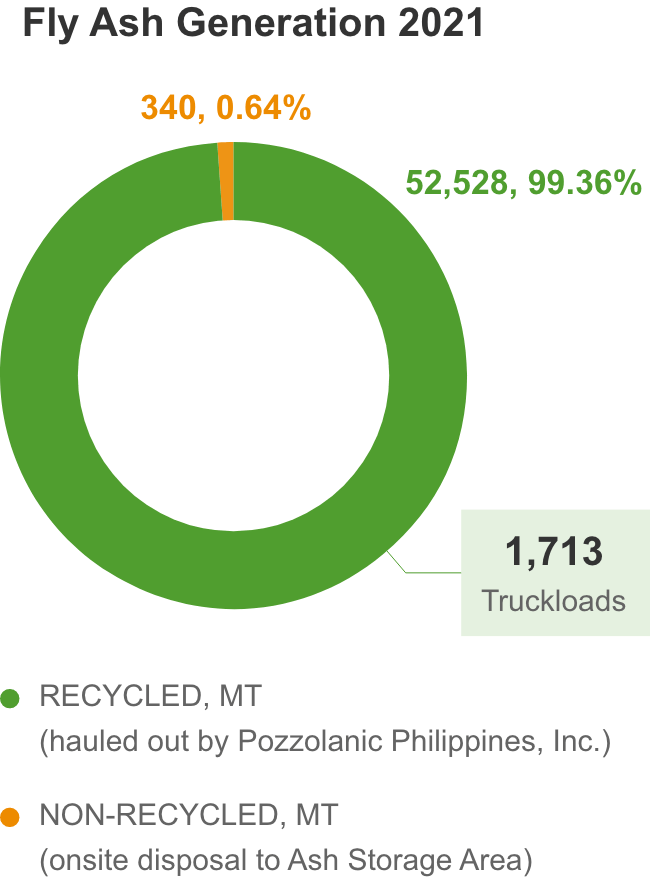

Quezon Power Plant Ash Management

Quezon Power Plant uses high-quality coal and Pulverized Coal Technology production process so that the fly ash and heavy ash produced by combustion which non-toxic.

Quezon Power Plant operates a recycling program in cooperation with Pozzolanic Philippines, Inc. to recycle fly ash as a raw material for cement production. and heavy ash to be recycled to fill roads with the Philippine Department of Public Works and Highways.

In 2021, there are

55,260.51 tons

of ash generated by the combustion of the Quezon Power Plant. 99.36% of the total ash is recycled and the rest of the ashes were taken to the landfill.

Recycling programs can help reduce the amount of fly ash and heavy ash required to landfills, thus saving limited storage space and avoiding greenhouse gas emissions up to 154,431.82 tonCO2e (as of December 31, 2021). Quezon Power Plant also uses the proceeds from the fly ash sales for community development projects.

Waste Disposal Reduction at Quezon Power Plant

In 2021, Quezon Power Plant managed non-hazardous waste by recycling waste and processing to be recycled, totalling 113.25 tons (as of December 31, 2021).

These wastes consist of Recyclable solid waste, unused concrete blocks, cutting branches donated to charcoal producers, scrap metal, food scraps donated to local communities to feed the wild boars, Plastic bottles donated for recycling and organic waste used as a precursor for composting vermicompost. These wastes accounted for 22.60% of the total non-hazardous waste processing for recycling.

Composting Area

Donation of Used Woods to Charcoal Maker