Sustainability Projects

Open Innovation

OPEN INNOVATION

Innovation is key to securing a company’s future. It directly correlates to business advancement, contributes to continuous development, and creates sustainability. Beyond just creating new products, the use of innovative methods and technology also maximizes company value and improves operational efficiency.

As EGCO Group looks ahead for new business opportunities and areas of growth, we recognize the importance of creating innovations to drive the organization towards sustainability and stay competitive in today’s dynamic landscape where advances in technology continue to transform the energy sector. As such, in addition to our collaborative efforts with business partners to create and further expand new innovations, we initiated the “EGCO Group INNERGY: Driving Sustainable Innovations from Within,” an open innovation competition to be a platform for inspiration and discover outstanding ideas that generate value for the company.

Project: Cooling Tower Energy Saving

The electricity generation process produces high-temperature water as a by-product that requires cooling before reusing. The cooling tower is one of the methods used to lower the temperature that is adopted at Khlong Luang Utility Power Plant. It was found that adjusting the pit angle of the turbine within the cooling tower could reduce electricity consumption by 438,876 kW/year, resulting in a reduction of 198 ton/year in greenhouse gas emissions.

Benefits of the Project

- Reducing electricity consumption and greenhouse gas emissions.

- Reducing electricity and fuel expenses.

- Enhancing employees’ skills to analyze machinery efficiency.

Implementation Approach

- Reducing the pit angle of the cooling tower’s turbine by 1 degree

2023 Performance

Project: KLU Smart Solution

From the STG lube oil leakage incident that caused a severe fire incident resulting in a steam turbine shut down for 3 months, EGCO Group established solutions and mitigation measures to prevent future incidents, which are divided into 4 steps as provided below.

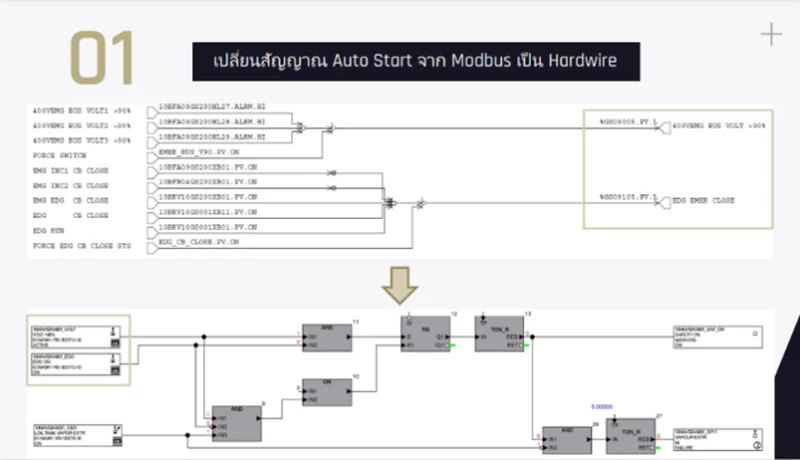

- Change the signal interface to hardwire.

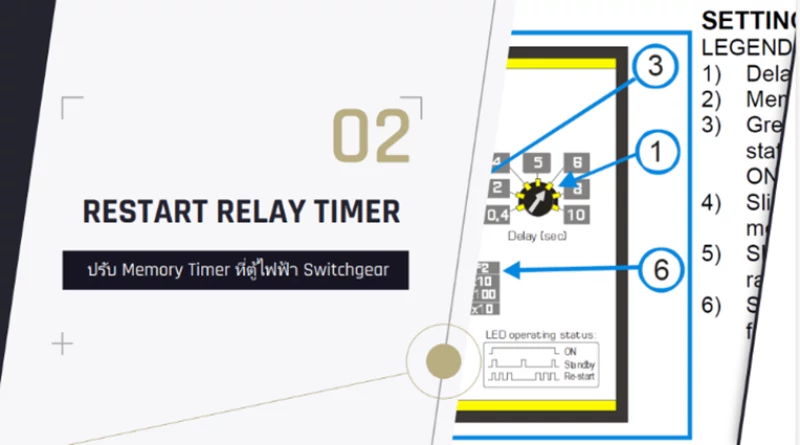

- Adjust the memory timer at the switchgear of the electricity distribution board.

- Increase the alarm annunciator window in the control room.

- Install DC lube oil vacuum fan and sensor.

Benefits of the Project

- Improving the efficiency of the steam turbine.

- The continuous operation of the steam turbine.

Implementation Approach

- Improvement of the components to address the leakage of STG lube oil.

2023 Performance

Project: ZeroLoss

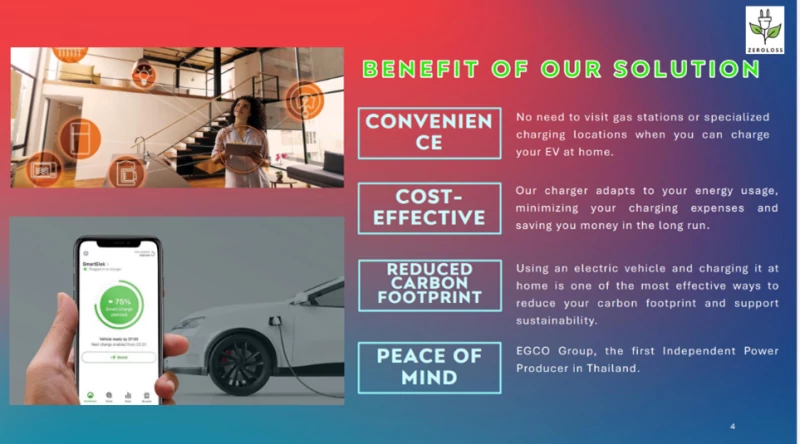

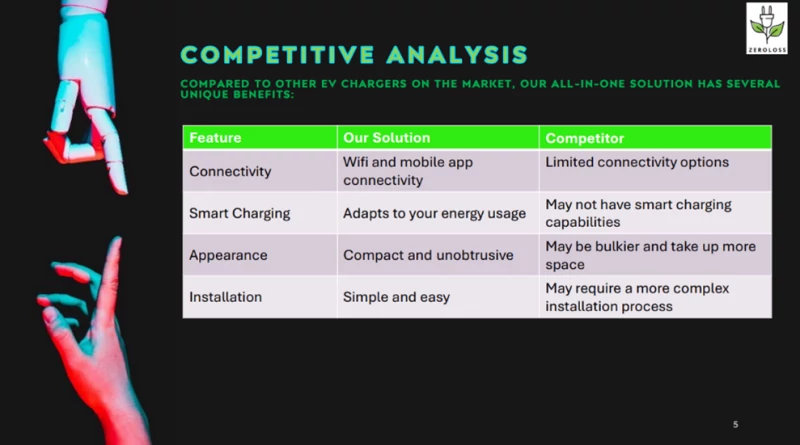

Due to the increasing trend of electric vehicles as a popular mode of transportation in the future, resulting from various reasons such as addressing environmental issues from the use of oil-powered cars or the worthiness of investment, battery charging equipment is essential for electric vehicles. The employees of EGCO Group have developed an "all-in-one EV charger," which is compact yet highly efficient. This home charger can be controlled from a smartphone and can reduce expenses with a smart charging function, unlike regular battery chargers. The battery charger can adjust the charging rate based on the individual battery usage of each vehicle.

Benefits of the Project

- More convenient in using electric vehicles.

- Lowering battery charging costs through the specialized function of this charger.

- Reducing greenhouse gas emissions by discontinuing the use of combustion vehicles.

Implementation Approach

- Producing battery chargers for electric vehicles which are expected to rise in the future.

2023 Performance