Sustainability Projects

Water And Wastewater Management 2023

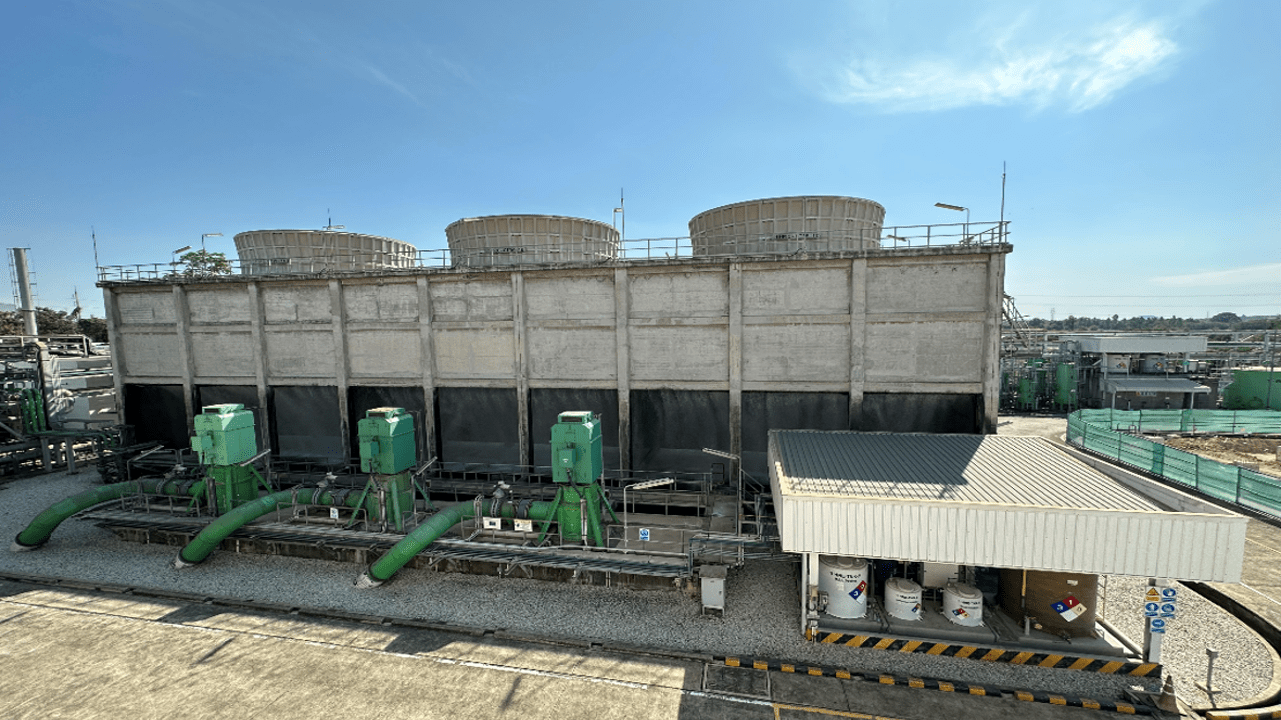

Water Reduction by Increasing Water Reuse Cycles in Cooling Tower of EGCO Cogen Power Plant

During the past years, EGCO Group has implemented the project to minimize water consumption in the power plant focusing on optimizing water usage as much as possible. In 2023, EGCO Cogen Power Plant has further continued with the project to increase water reuse cycles in cooling tower of the power plant after it was proven effective during the implementation in 2022. The objective of this project is to minimize wastewater discharge from blowdown cooling tower by increasing number of water cycles in water treatment system. This project helps reduce the costs of raw water and chemical usage in cooling tower, as well as decreasing scaling and calcium and manganese accumulation in the system.

Benefits of the Project

- Reduction of raw water usage in the power plant.

- Reduction of chemicals used in cooling tower.

- Reduction of cooling tower management costs.

Implementation Approach

- Increase the number of water treatment cycles in the cooling tower from 8 cycles to 11.7 cycles.

2023 Performance

Wastewater Treatment for Reusing Water in the Power Plants

All power plants overseen by EGCO Group have efficiently implemented water management plans and wastewater treatment processes with the target to optimize water consumption to the full extent. Wastewater will flow into the final retention ponds, where its quality is sampling and monitored to ensure it meets the criteria for reuse at the operation site.

For example, Ban Pong Power Plant and EGCO Cogen Power Plant reuse the treated wastewater from the final ponds to water their gardens and clean the floor within their facilities, which helps cut down the cost of water consumption of the plants.

Benefits of the Project

- Reduce amount of wastewater discharged into public water bodies.

- Reduce the cost of water usage of the power plants.

Implementation Approach

- Reuse the treated wastewater from wastewater treatment system within the power plant area.

2023 Performance

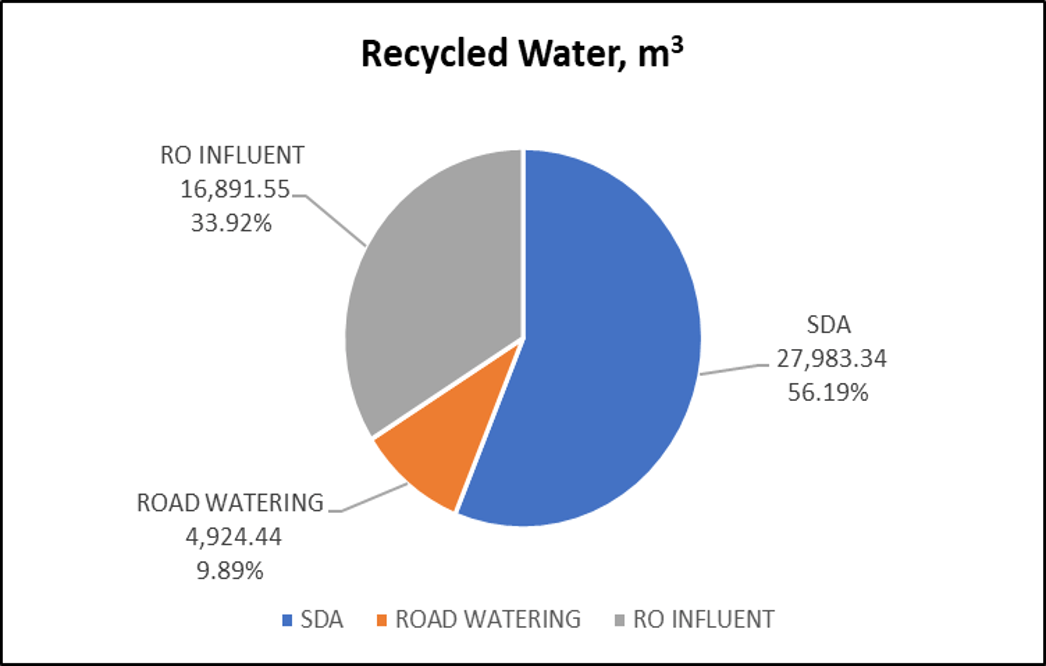

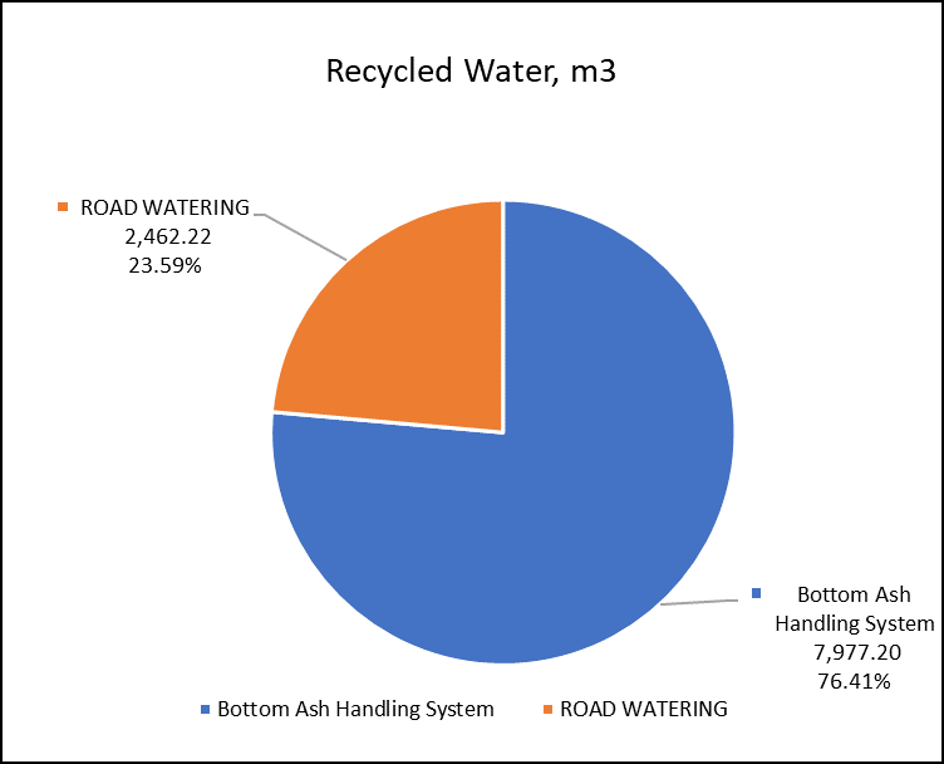

Reuse of Treated Wastewater within Quezon Power Plant (QPL) and San Buenaventura Power Plant (SBPL)

As part of the commitment to use resources responsibly, treated wastewaters are reused in process operations that can utilize recycled water in San Buenaventura Power Plant (SBPL) and Quezon Power Plant (QPL) for the following purposes.

- WWCB wastewater for Spray Dryer Absorbers (SDA) spray water for the reduction of flue gas temperature prior to Electrostatic Precipitator (ESP) entry;

- Road watering to reduce dust excursion; and

- Influent for Reverse Osmosis (RO) unit.

- Treated Effluent Pond (TEP) treated wastewater recycled for use at Bottom Ash Handling System (BAHS)

Benefits of the Project

- Reduce amount of wastewater discharged into public water bodies

- Reduce greenhouse gas emissions from wastewater.

Implementation Approach

- Reuse the treated water from wastewater treatment system within the power plant area

2023 Performance

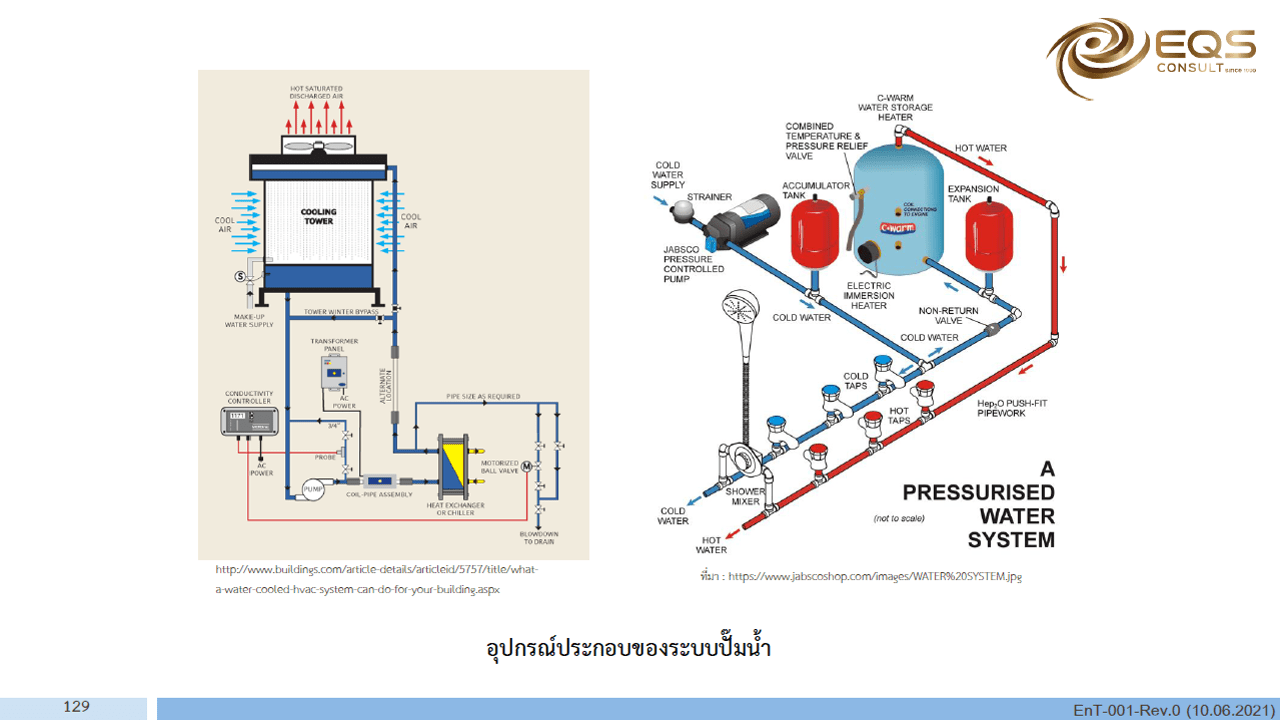

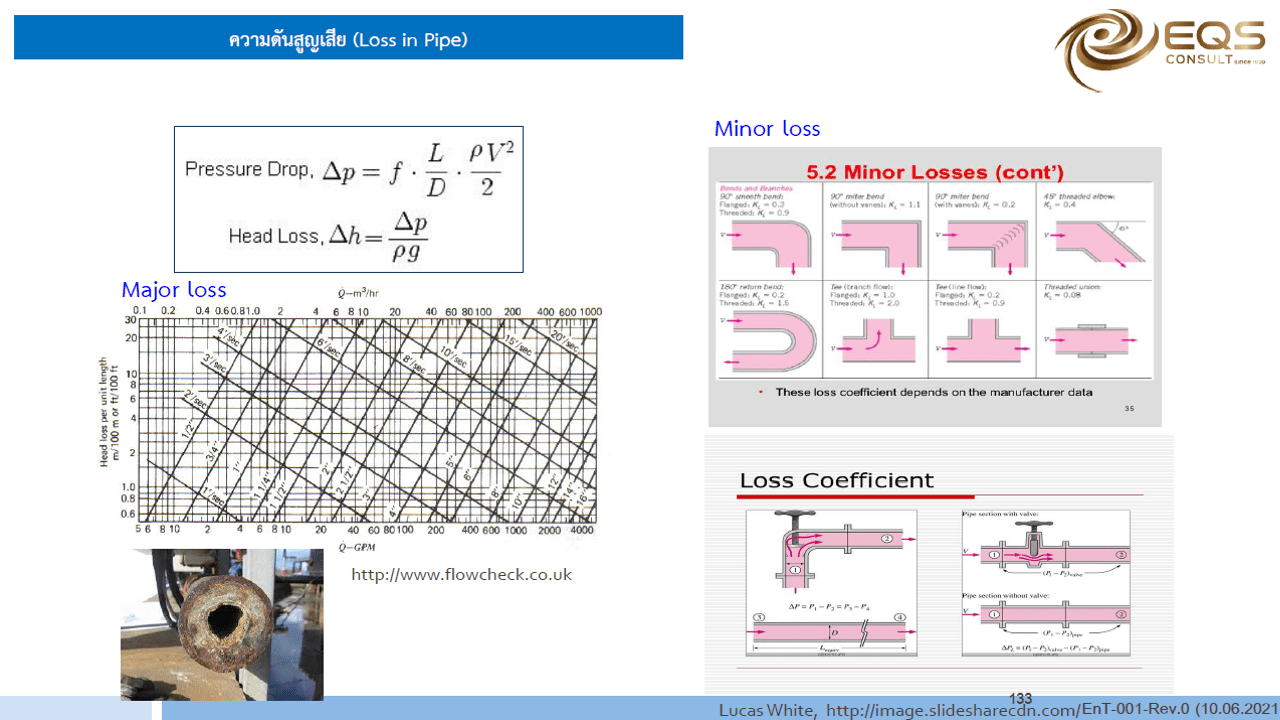

Resource Efficiency Through Engineering Approach Training

As part of a resource efficiency awareness training program, EGCO Group has introduced engineering strategies to enhance operational efficiency. The training focused on improving equipment performance, including water-operating machines, through measures such as reducing water leaks, optimizing pump sizes to align with production needs, enhancing blade and rotation configurations, and conducting thorough maintenance. Held at EGCO, the session was attended by 37 participants, equipping them with practical skills to optimize resource use.

Benefits of the Project

- Equip the participants with knowledge on operational efficiency.

- Reduce amount of energy and water loss in the production.

Implementation Approach

- Improve equipment performance via engineering approach.

2023 Performance