Sustainability Projects

Safety Training Project

Year 2022

Safety Training Programs

Ensuring occupational health and safety are core priorities for EGCO Group. This means that beyond implementing management systems and electricity generation work processes that meet safety standards and can secure the trust and confidence of our external stakeholders, we place the occupational health and safety of our employees, suppliers, contractors, and other relevant stakeholders at the heart of our operations. EGCO Group regularly organizes training and refresher training sessions on safe work practices in power plants and other Company operations for employees. This training serves to equip employees with the knowledge and skills to perform their tasks with caution, always prioritize safety, and minimize the risk of accidents occurring in the workplace.

Training Program on Disaster Prevention and Emergency Preparedness Planning

EGCO recognizes that during uncontrollable or unforeseen events, such as natural and man-made disasters, clearly defined measures are crucial to ensuring effective emergency response, maintaining business continuity, and minimizing impacts on people, assets, and the environment.

Thus, EGCO Group has prioritized emergency preparedness and response as a critical strategic task. The Company has established an emergency preparedness and response procedure and defined an incident command system to ensure preparedness in all dimensions - including command, control, coordination, and communication during emergency incidents, as well as performance monitoring, planning, and organizing emergency response exercises and drills for all types of incidents. Through these measures, EGCO ensures the organizational capability to respond to incidents in a timely and effective way.

EGCO Group has developed a training program on emergency preparedness, targeting functions involved in occupational health, safety, and the environment. The training covers the following topics:

- Understanding relevant rules, regulations, and standards

- Risk assessment and emergency planning

- Communicating and managing emergency plans

- Business continuity risk management

- Management review

Benefits of the Project

- Functions involved in occupational health, safety, and the environment can develop emergency response measures to reduce the severity of impacts on people, assets, production processes, and the environment.

- Functions are equipped to act appropriately in the event of emergency incidents to enable effective emergency response and recovery and ensure business continuity.

- Emergency response measures align with ISO 14001:2015 (4.4.7 Emergency Preparedness and Response) and ISO 45001:2018 (8.2 Emergency Preparedness and Response).

Implementation Approach

- Implement a two-day training program that builds a strong understanding of the emergency preparedness plan.

- Training includes lectures delivered by experts, practical exercises, and collaborative situation analysis.

2022 Performance

Training Program on Rules, Regulations, and Standards on Occupational Health, Safety, and Environment

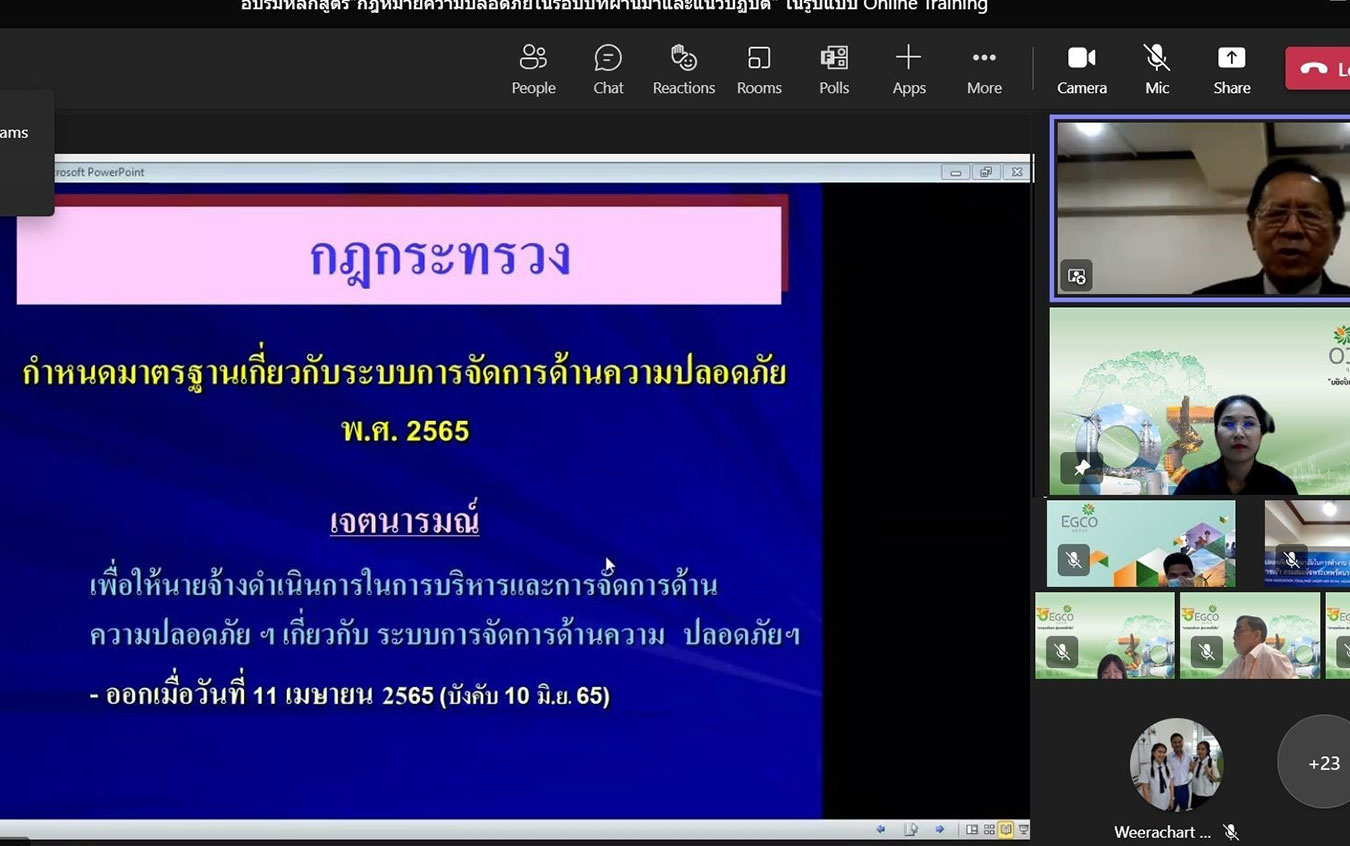

In 2022, in response to changes in relevant regulatory requirements, EGCO Group organized training on the following occupational health and safety regulations:

- Occupational Safety, Health, and Environment Act B.E. 2554 (2011)

- Ministerial Regulation on the Prescribing of Standard for Administration and Management of Occupational Safety, Health, and Environment for Work Related to Machines, Cranes, and Boilers B.E. 2564 (2021)

- Ministerial Regulation on the Prescribing of Standard for Administration and Management of Occupational Safety, Health, and Environment for Work Related to Scaffolding and Props B.E. 2564 (2021)

- Ministerial Regulation on the Prescribing of Standard for Work Related to Radiation B.E. 2564 (2021)

- Ministerial Regulation on the Prescribing of Standard for Safety Management Systems B.E. 2565 (2022)

- Other relevant regulations

Benefits of the Project

- EGCO Group operators can complete tasks safely and apply knowledge of relevant regulations to their work.

Implementation Approach

- Organize a six-hour, online training program with lecturers from the Safety and Health at Work Promotion Association (Thailand).

2022 Performance

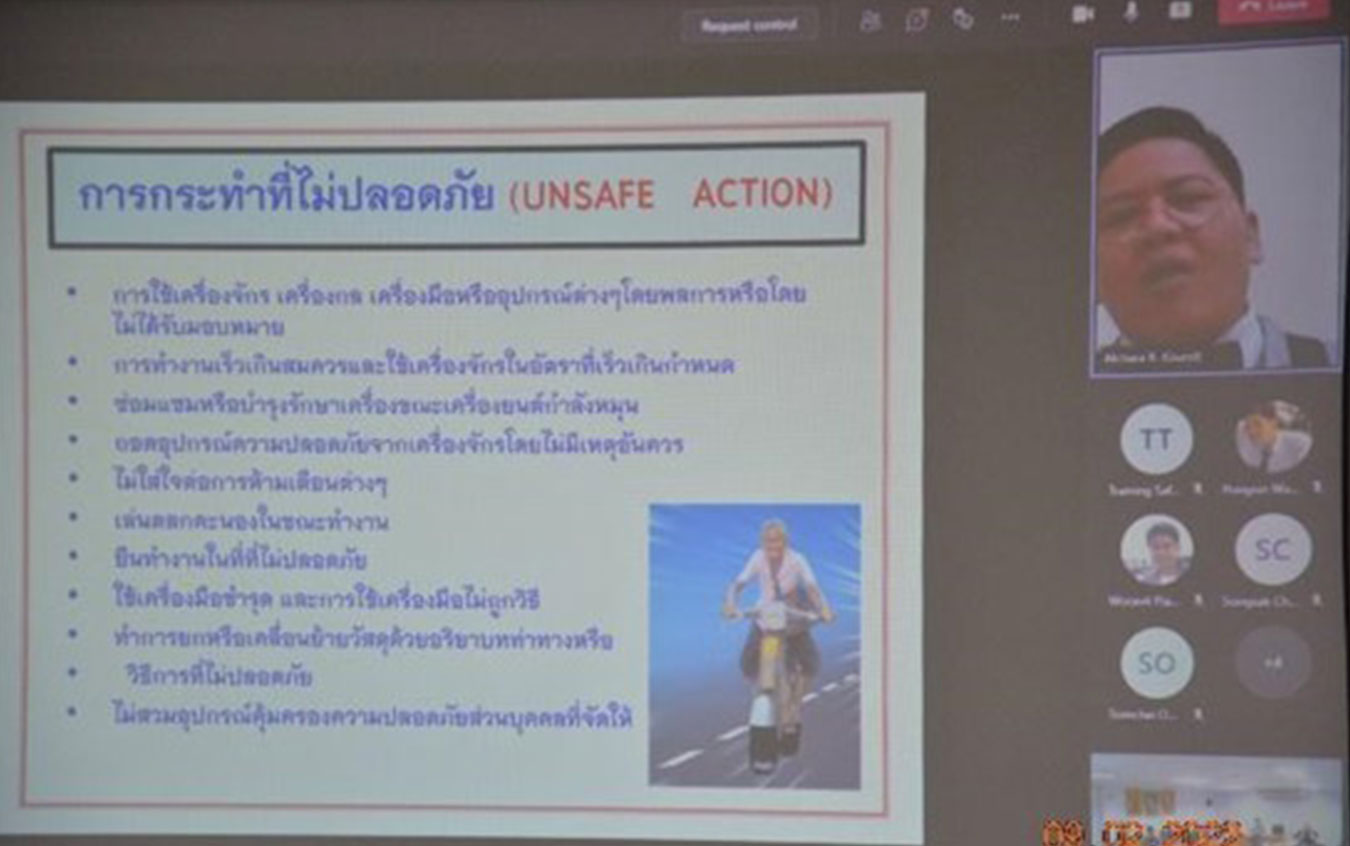

Training Program on Building Safety Awareness

Other than ensuring employee understanding of safety regulations, setting good practices, and promoting safety in the workplace, EGCO Group places importance on strengthening safety awareness amongst employees in order to reduce accidents and minimize safety risks in the workplace.

EGCO Group has thus developed the Safety Awareness training program for operators and workers at the Khanom Power Plant and Banpong Utilities Power Plant. The training aims to deliver the following objectives:

- To provide basic knowledge on safe work practices for operators

- To build safety awareness and understanding for operators and promote behavioral change towards improved safe practice.

- To ensure work processes are completed without accidents or damage to the organization

Benefits of the Project

- Operators and other employees responsible for safety management understand the risks inherent in their work and are equipped to manage those risks.

- Operators and other employees responsible for safety management have safety awareness and understand the impacts that may result if workplace safety measures are neglected.

Implementation Approach

- Organize a two-day, hybrid training - offering attendees an option to attend online or in-person - for operators and workers of the Khanom Power Plant and Banpong Utilities Power Plant.

2022 Performance

Safety Week

All EGCO Group power plants organized a “Safety Week” to promote employee awareness and understanding of safety practices. Through this initiative, different power plants organized a variety of activities for employees. For example, during its Safety Week, the Khanom Power Plant organized a safety trivia activity, a lecture on safety outside work, a competition on wearing personal protective equipment (PPE), and a lecture on building awareness of safety, energy, and the environment.

Meanwhile, the Safety Week event at the Solarco Power Plant featured a safety slogan contest where participants competed for the best safety slogan for 2022, a basic first aid training activity, and a lecture on traffic laws.

Benefits of the Project

- Power plant employees have improved awareness of workplace safety.

- Participants of the event obtain knowledge of safety practices.

- Accident risks are reduced.

Implementation Approach

- Organize activities under the “Safety Week”, including inviting speakers to give lectures on safety and holding trivia or other activities that test the safety knowledge of power plant employees.

Employee Training on Safety Management Diagnosis

EGCO Group, in collaboration with ERM-Siam CO., LTD. ("ERM"), has conducted a comprehensive employee training program on safety management diagnosis. This program is designed to enable employees to identify potential safety concerns or challenges and develop effective strategies to mitigate them. By equipping employees with the necessary skills to detect root causes of safety issues, the training facilitates the process of conducting safety management diagnosis, which is vital for creating corrective action plans and ensuring the safety of operations.

The training involves interviewing employees at selected sites under EGCO's control and providing guidance throughout the process of identifying root causes of safety concerns or challenges. This approach allows employees to gain practical experience and enhance their understanding of safety management diagnosis. The main objectives of this training program are as follows:

- Enhance employees' proficiency in determining the root causes of safety issues arising from day-to-day operations.

- Gain a comprehensive understanding of the safety management status within their operating site.

- Foster a culture of safety awareness and promote a positive safety-oriented mindset among employees engaged in project execution.

Benefits of the Project

- Employees gain skills to identify and address safety concerns.

- Enhancing safety-oriented mindset among employees.

Implementation Approach

- Interview sessions with safety officers, plant managers, and members of the EGCO Group Occupational Health and Safety Committee.

- Fieldwork observations in the field area with EGCO’s employees to analyze and develop short-term and long-term plans

2023 Performance

Training Program on Hazard Recognition Training (HRT) and Field Safety Coaching

EGCO Group recognizes that safety is the most important key to be considered in any operations as any accidents that occurs will affect every part involved in the process. However, accidents are not entirely uncontrollable or unforeseen. Prevention and mitigation actions can be planned ahead of time if the hazard has been identified.

Thus, EGCO Group, together with ERM-Siam CO., LTD. (“ERM”), have developed a training program on Hazard Recognition Training (HRT) and Field Safety Coaching for plant/project managers, plant operation managers, and supervisors at the operating plants under EGCO’s control. The training aims to deliver the following objectives:

- Understand the safety values within EGCO Group, as well as the safety systems currently implemented.

- Understand risks and hazards that are already present within the EGCO Group.

- Develop the awareness and hazard recognition skills of Plant/Project Managers, Operation Managers, and Supervisors.

- Practice communication skills to intervene in any unsafe acts and conditions.

- Develop trainers/champions within the EGCO Group.

Benefits of the Project

- Improve the management system and enhance consistency across the group.

- Reduce the risk and potential loss of life from any incidents due to inappropriate safe work practices.

- Enhance safety awareness and culture within the EGCO Group

Implementation Approach

- Classroom training sessions to coach Plant/Project Managers, Plant Operation Managers, and Supervisors.

- Field coaching sessions to train operators at EGCO’s power plants.

2023 Performance

Year 2021

Safety Training Project

EGCO Power Plants and Operations are regularly organize the training and review the courses for safety training to ensure the proper work and in line with the relevant standards, laws and regulations. This is to ensure that employees are knowledgeable and ready to work in order to reduce the risk of hazards and minimize the potential damage.

Below are the examples of safety training from EGCO Operations, EGCO Engineering & Service Co., Ltd (ESCO).

Overhead Crane Operator, Controller and Signaler Refresher Training

| Description of the Program & Program Objectives | Business Benefits | Percentage of FTEs Participating in the Program |

|---|---|---|

|

|

Proportion to total employees (Maintenance Division): 20.79% |

Participants:

- ESCO employees: 27 persons (from the maintenance division)

Training Approach:

- Lecturing sessions: Related laws and regulations for Overhead Crane activities including Ministerial Regulations Determining Standards for Administration and Management of Occupational Safety, Health and Working Environment Regarding Machinery, Cranes and Boilers, B.E. 2021.

- Workshop: Group activities, case studies of crane accidents and their impacts as well as analyzing investigation results of accidents for preventive planning.

- Operation safety for activities that require different crane types from a normal operation.

Certificate of Overhead Crane Operation:

Confined Space Working Refresher Training

| Description of the Program & Program Objectives | Business Benefits | Percentage of FTEs Participating in the Program |

|---|---|---|

|

|

Proportion to total employees (Maintenance Division and Operation Division): 39.74% |

Participants:

- ESCO employees: 25 persons (from the maintenance division and the operation division)

Training Approach:

- Lecturing sessions and in-house activities

- Related laws for working in confined spaces

- Type of confined space

- Hazard identification and assessment, and site conditions assessment

- Preparation for working in confined spaces

- Safety operation methods in confined spaces

- The use of personal protective equipment, rescue devices in confined space

- Process to obtain/withdraw a permit for working in confined spaces

- Safety power cut-off principle

- Roles and responsibilities of the project approver, supervisor, and operator in confined space

Certificate of Overhead Crane Operation: